Microchip Car Cockpit Demo

Designed and fabricated from scratch in Solidworks. Packs down into 3 Peli cases for easy shipping. All demo software designed, and coded by Nigel. Includes – Ultrawide displays, KoDs, DoK, Touchpads, induction sensor, rear view cameras, media player, offline mapping demo, wireless phone charging and LED lighting. Even added Sega racing game which uses the wheel! Microchip website

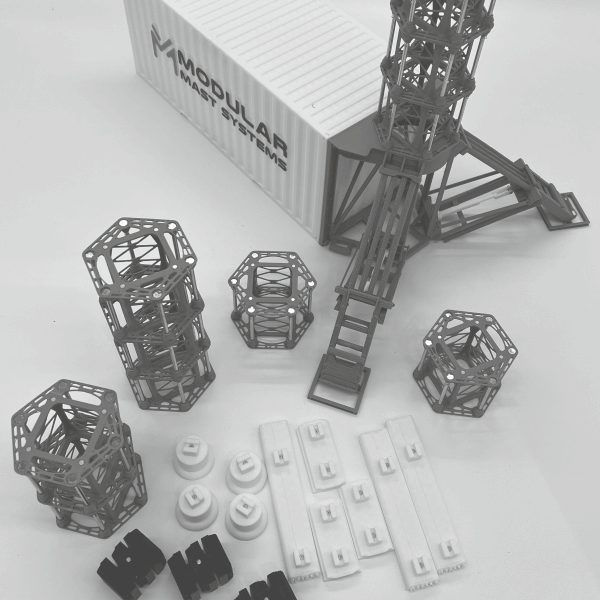

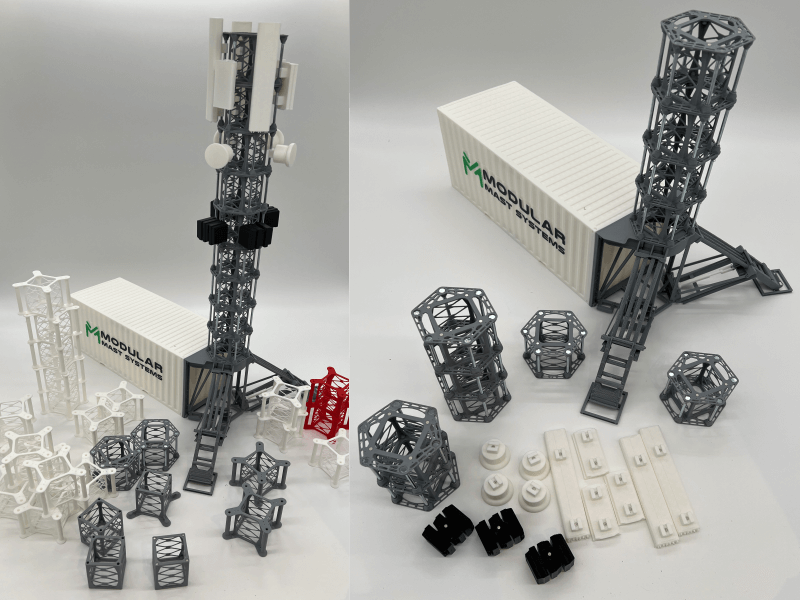

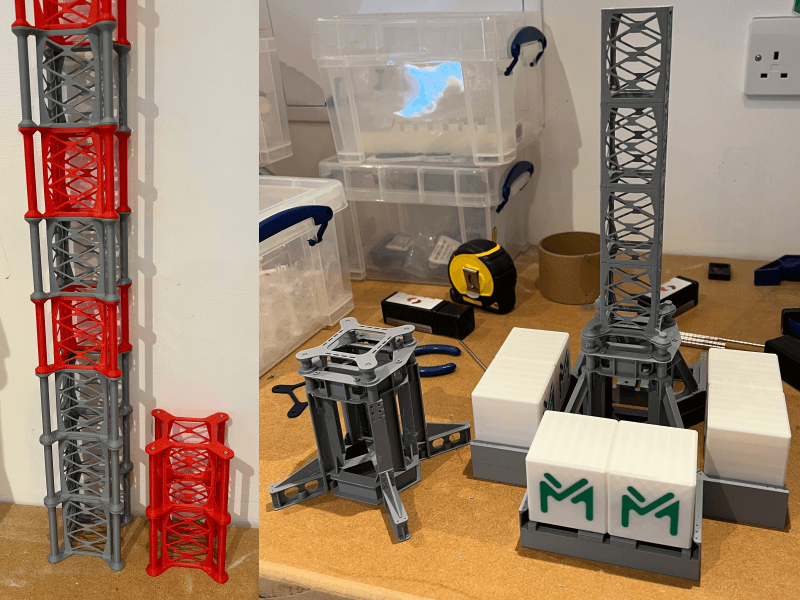

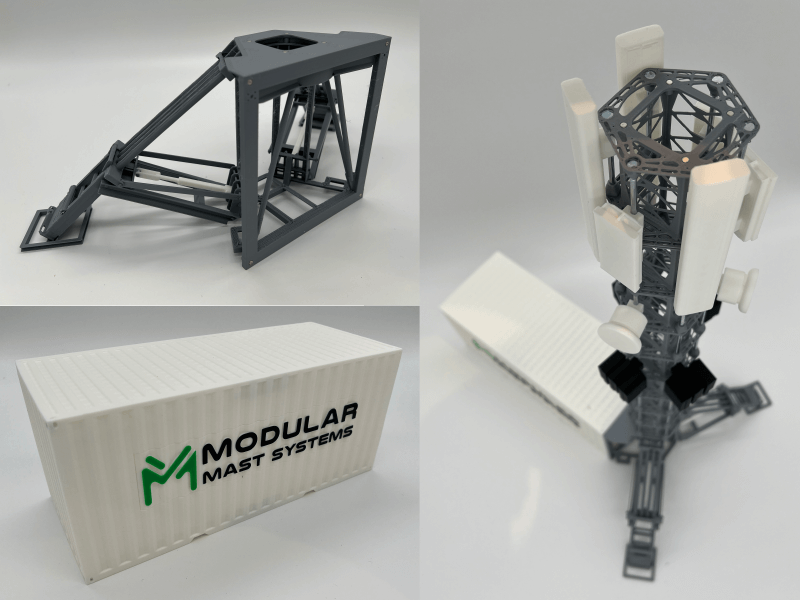

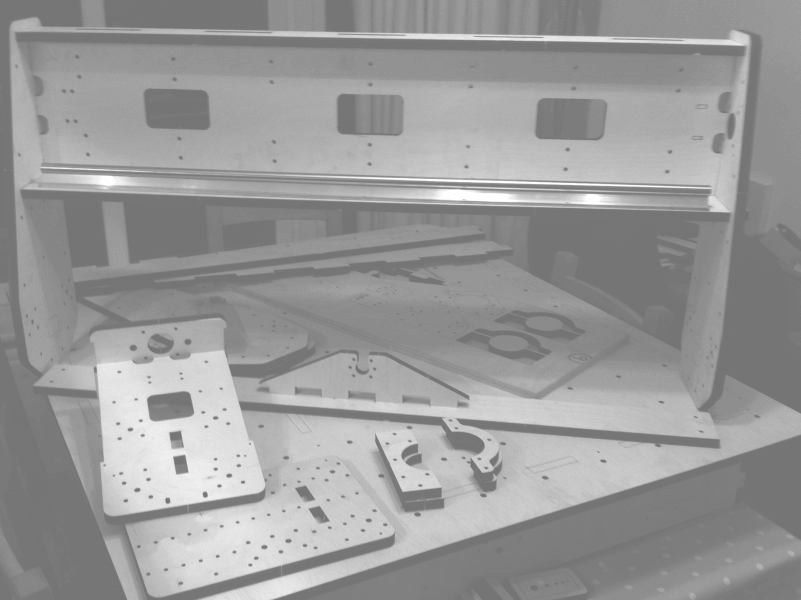

Scaled model of mobile phone mast system

Client wanted model of configurable mast system they produce and deploy. Using their original CAD data we adjusted the designs to optimize for 3D printing, including adding magnets into the design for easy reconfiguration, allowing the model to be adapted for different scenarios. Printed the model in-house on our multiple 3D printers for quick turnaround. Delivered a portable, eye-catching model that can be showcased at client meetings and trade shows.

Raspberry Pi Scrolling Matrix Sign

Fun project created for children to try hand at soldering, electronics and assembly. The sign uses a Raspberry Pi and ws2812 LED strips. Code was written to allow full control on the messages and colours via a web browser. Two buttons also allow recall of preset messages. The unit is constructed from laser cut plywood and includes a thin veneer wood as the front cover allowing the LEDs to shine though. Can be either battery or main powered.

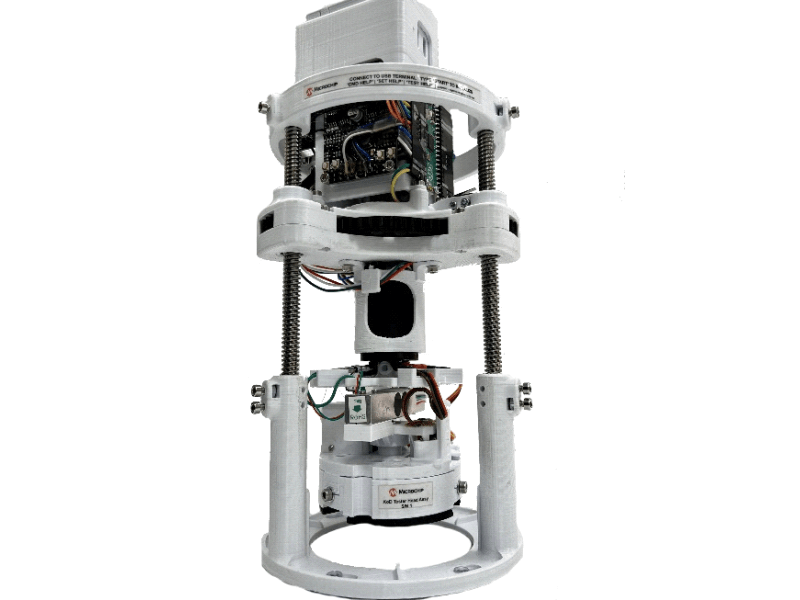

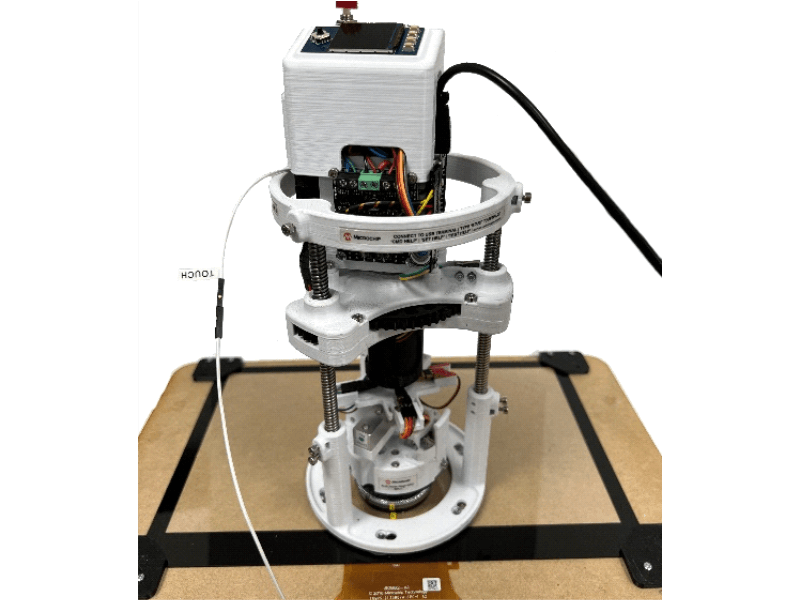

Knob on Display Tester for Microchip

Knob on Display automatic tester, designed, fabricated and coded. Allows repeated rotation and push testing on KoD knobs. Users can configure the test parameters and create own custom test as well as run standard inbuilt tests. Includes load cell to grip knob with desired pressure. Designed to be not too costly to produced and non conductive around head.

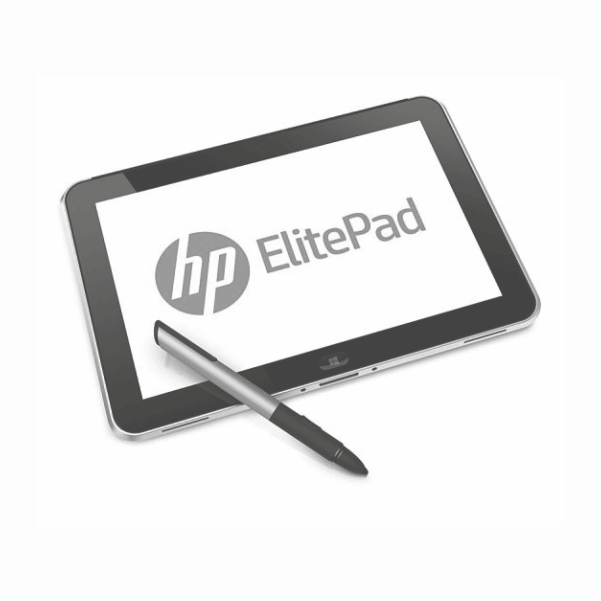

HP Active Stylus for Capacitive Touch Sensor

HP active stylus project, worked with HP in the design phase and various pre-production builds at factories in China.

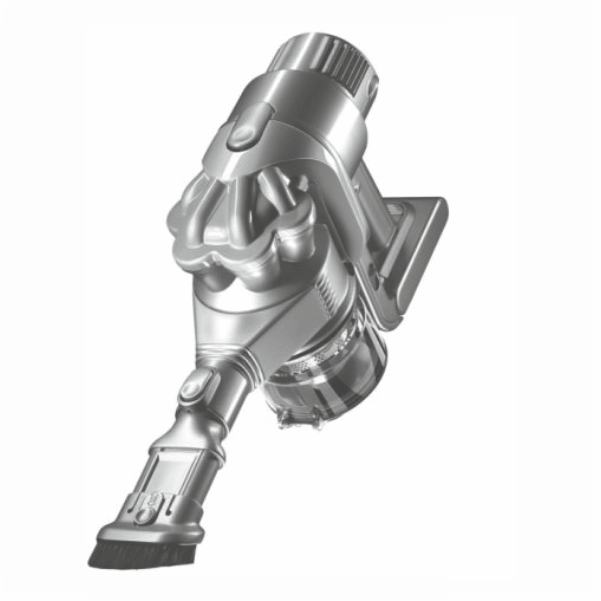

Dyson DC16 First Dyson Handheld Vacuum

Dysons first handheld vaccum. Key member of the design team, had responsibility for the motor bucket assembly. Involved working closely with the computational fluid dynamics team to design the motor impeller and ducting along with electronics team to house the drive circuitry. Various prototypes designed and produced, including multi axis CNC, rapid prototyping, both SLS and blue stone SLA. Assembly fully designed validated, tooled and put into production in record time.

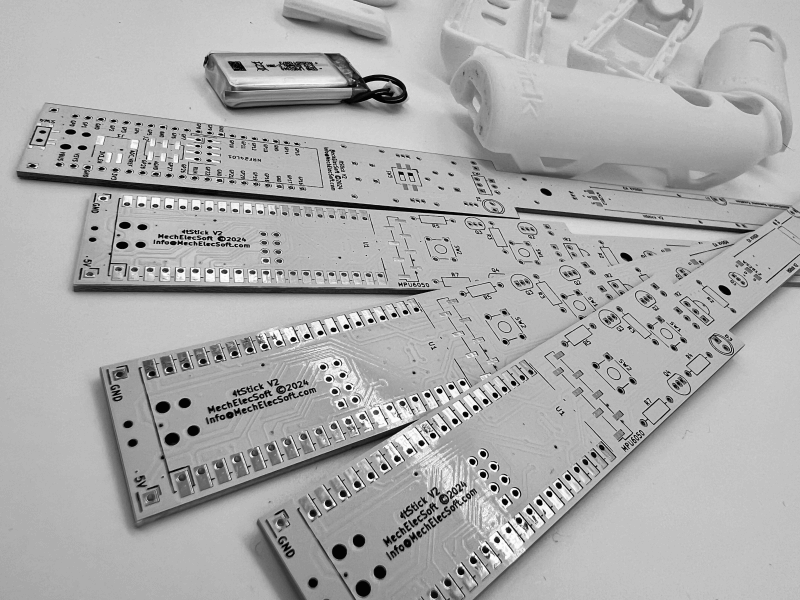

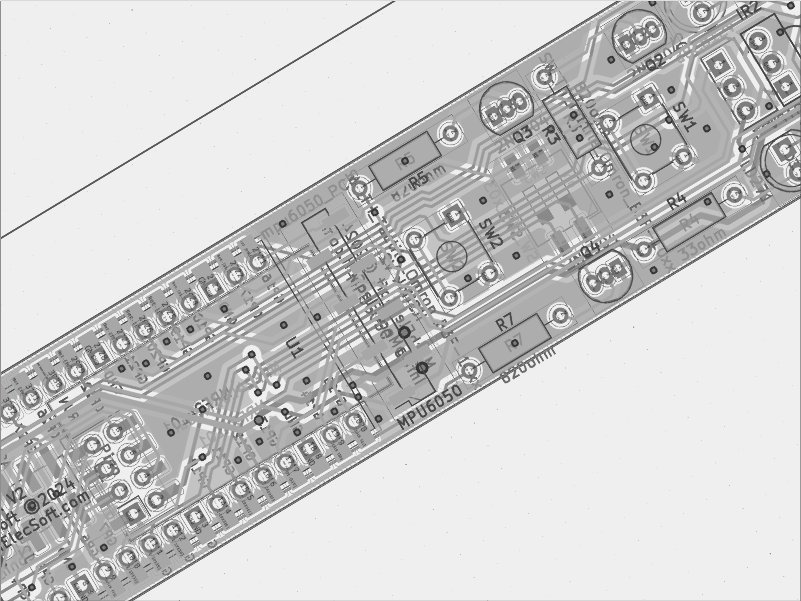

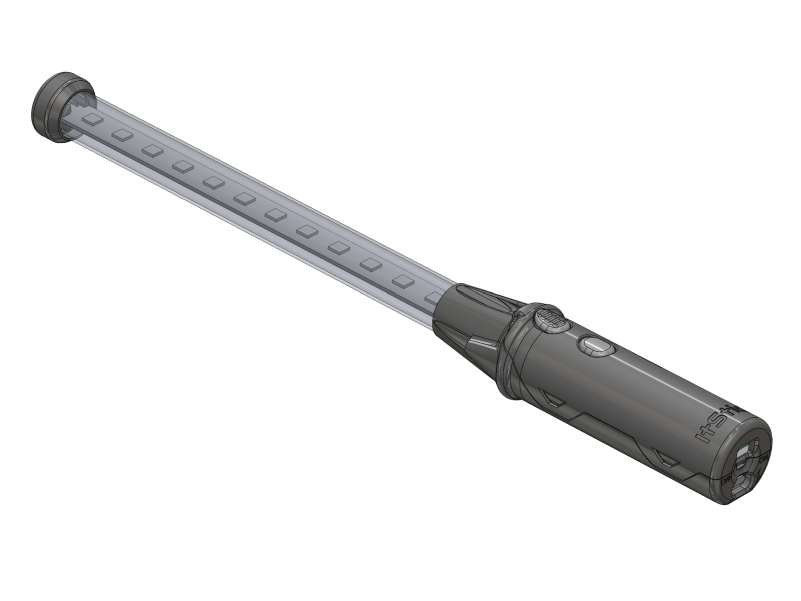

ItStick Game

ItStick toy development, an interactive light stick toy for children. Comms between sticks takes the game of It/Tag to a new levels!

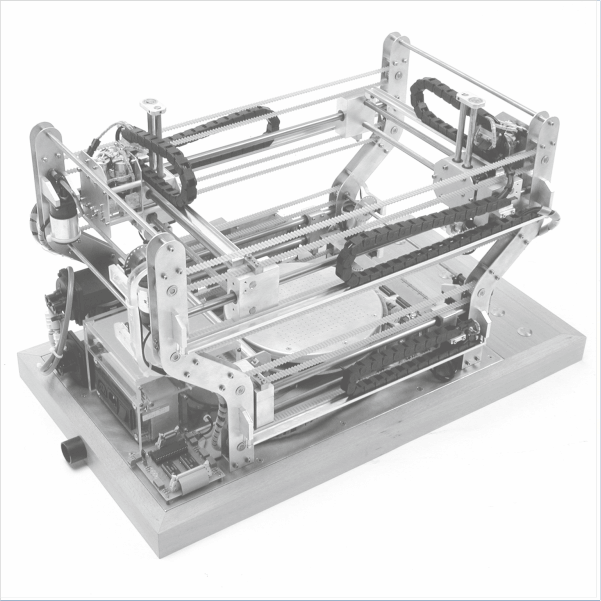

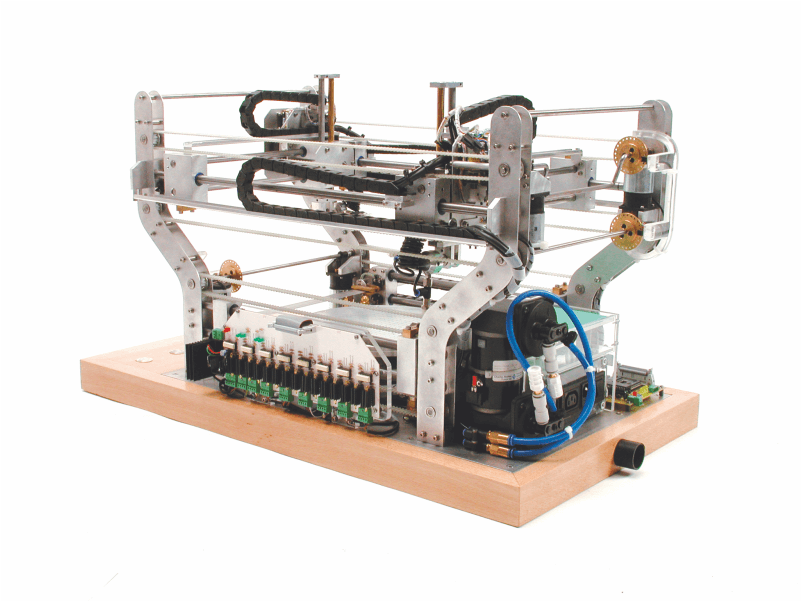

Interactive Origami Machine

Nigel's final year University project. A robotic paper-folding machine capable of producing origami sculptures from single sheets of paper. Designed in Pro Engineer, comprises of 2 overhead XYZ suction cups with rotating arms, rotating vacuum bed, movable roller and ruler clamp, all PIC Microcontroller controlled. This project shows how complex human activities can be to duplicate. Sponsorship was obtained from various companies and the Audi Design Foundation.

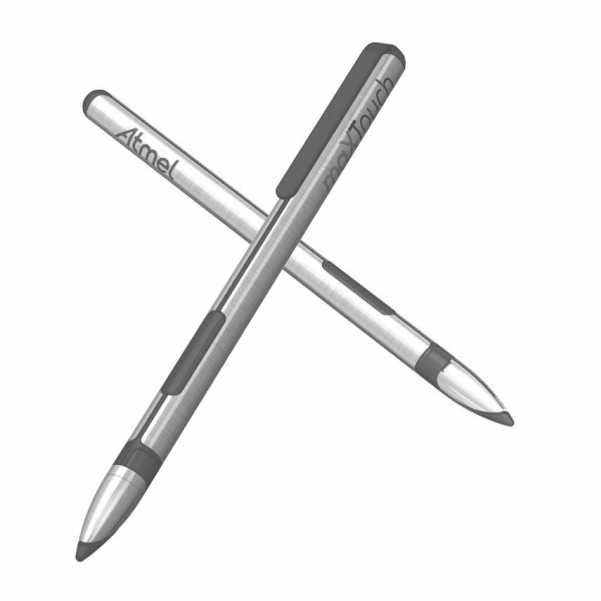

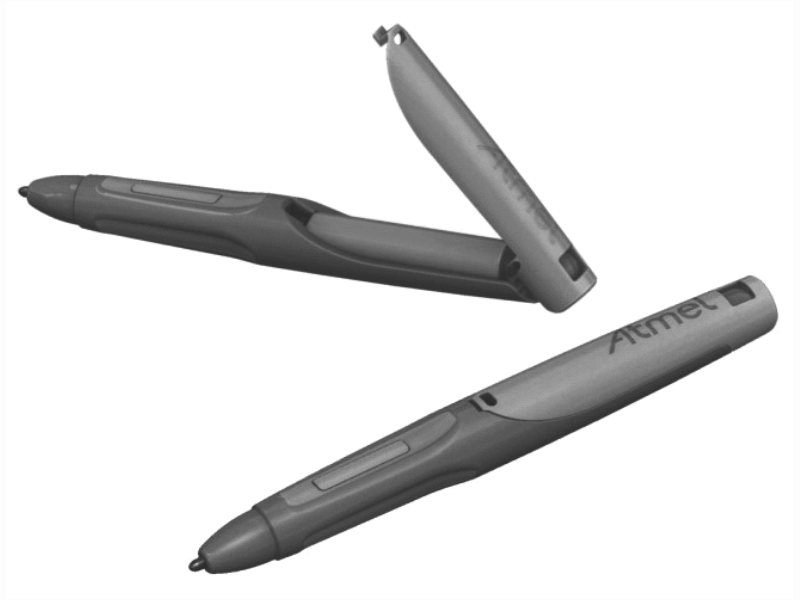

Active Stylus for Capacitive Touch Sensor

Nigel was the lead mechanical engineer for the development of Atmels MaxStylus active stylus. Worked with partner manufacturers based in Taiwan & China to produce and put into production the Atmel active stylus and customer designs. Involved from initial concept generation to mass production, customer support and consultation. Included Asia visits for design phases, trial builds, production runs, testing and support. This particular Atmel development stylus uses a lithium rechargeable battery. A dock was also produced to allow the Stylus to be recharged and re-programmed. It also featured a clip-on removable tip design acting as the transmitter.

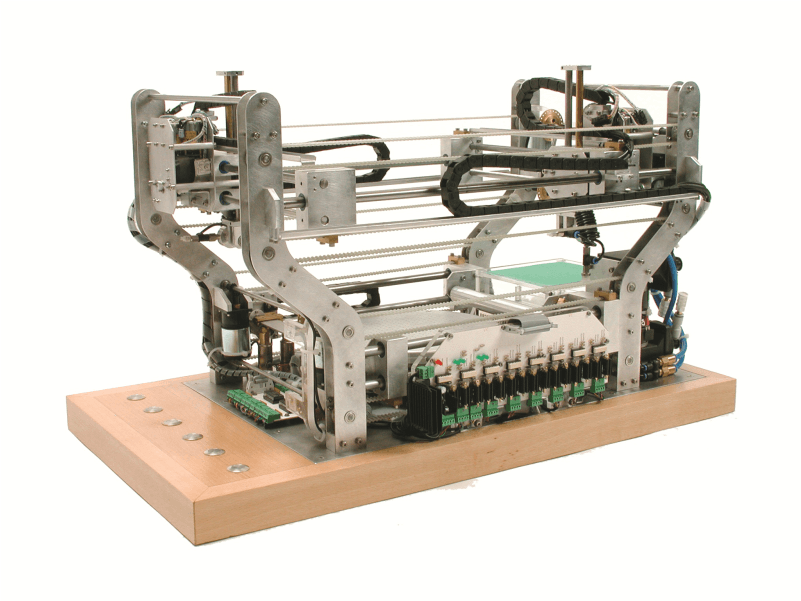

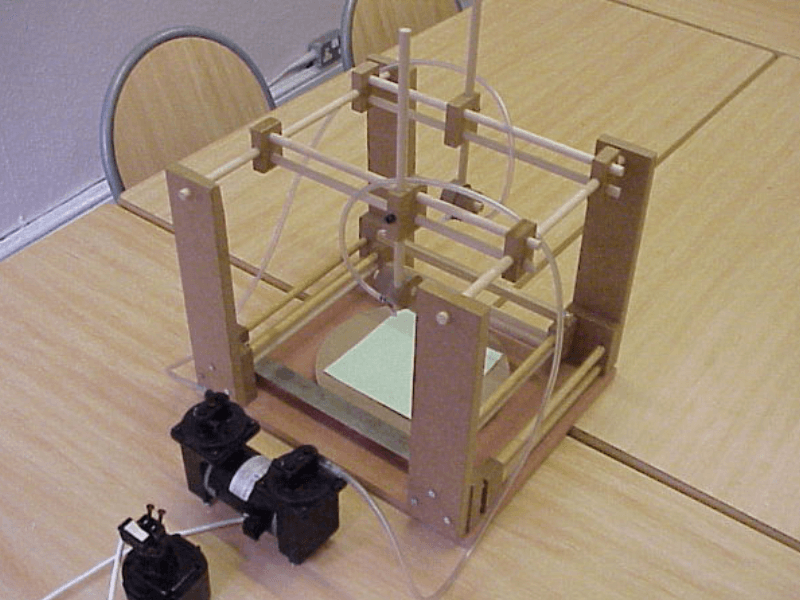

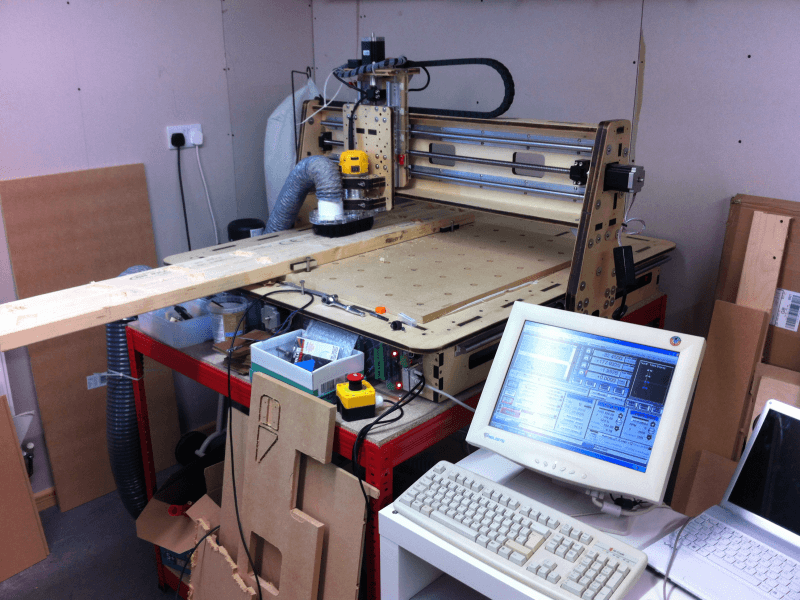

3 axis CNC Machine

3 axis CNC router machine designed in SolidWorks for cutting wood. Manufactured from laser cut birch plywood. Uses Nema 23 stepper motors and a Dewalt router controlled by Mach3 industrial software.

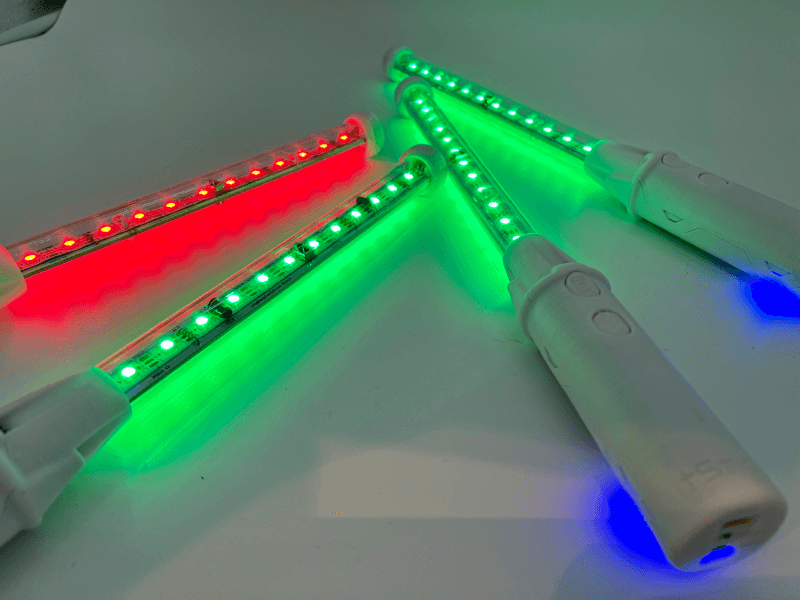

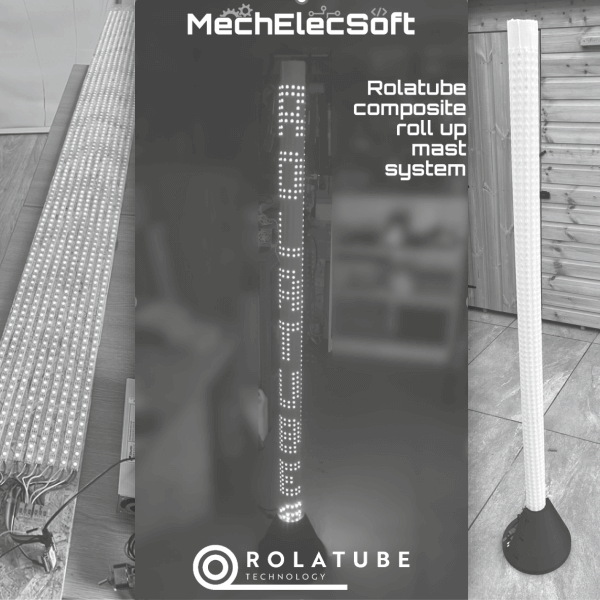

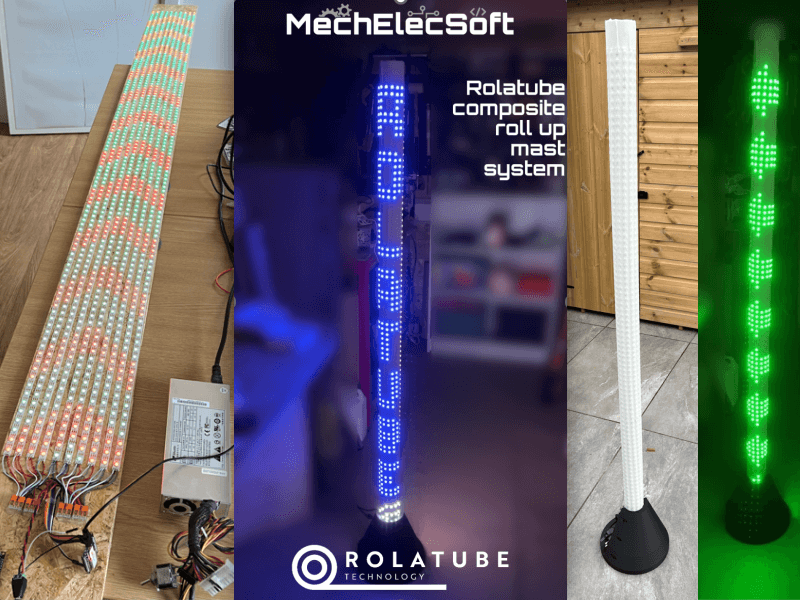

Rolatube composite roll up mast fitted with 2100 addressable LEDs.

We had fun time integrating 2100 addressable LEDs into one of their innovative composite roll-up mast tubes.

The result? Over 4 minutes of dynamic, custom light shows, featuring: Animated Rolatube logos, Moving chevrons & arrows, Traffic lights, Strobe effects, Moving rings, VU meters

From hardware fabrication to programming, this project was all about pushing creative boundaries and delivering an eye-catching visual experience.

Got a project in mind? Let’s talk and bring your vision to life!

Quick Fabric Fastener

A simple twp piece clip design for attaching to fabric material and allowing easy tie down.

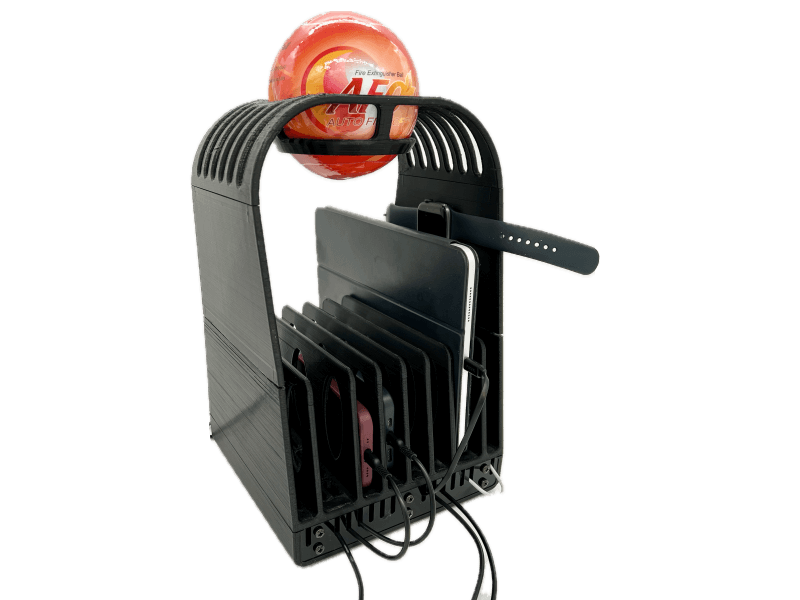

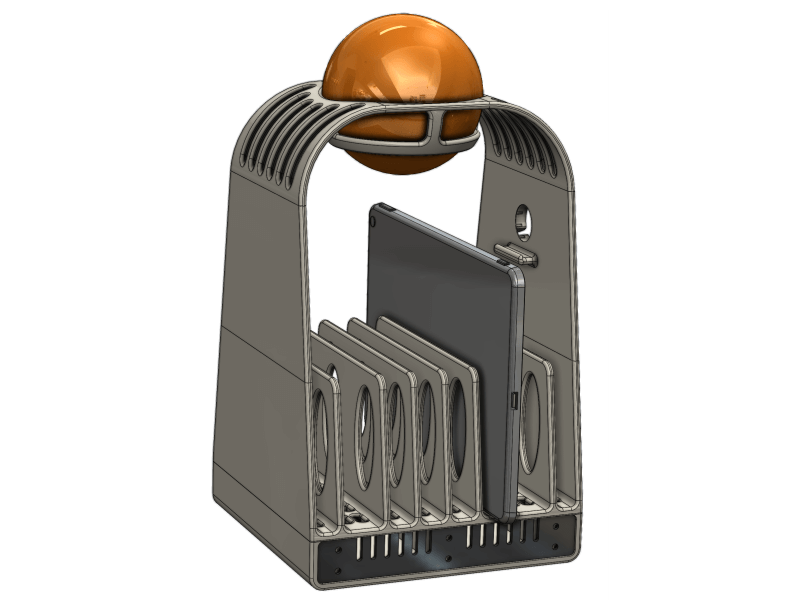

Device Charging Station

A device charging station for mobiles, tablets and wearables with built in fire suppression. Ideal for families where all devices can be changed safely in one place at night eliminating the need for children / teenagers to have devices on charge next to beds etc. All cables can also be secured so they cannot be removed. Promotes a healthy and safer device routine. Fire suppression done via a power fire extinguisher ball located in the top of the station.

Dyson Robot

Involved in the development of various versions of the Dyson robot. Oversaw extreme life testing of mains electrical cable management / handling systems. R&D work into new robot systems included patent for a method of emptying a robot bin. Had responsibility for the motor bucket assembly and user interface controls on a later battery robot which evolved into the 360 eye.

Custom PSU and dimmer housing

Custom PSU and dimmer housing designed and fabricated in house from ABS

Dyson DC12 First Dyson Japanese Vacuum

First Dyson cylinder vacuum cleaner design specifically for the Japanese market. Assisted with building and assembling rapid prototypes, working on modifications and feeding back into design team for final tooling. Helped with pre production builds, user trails and testing.

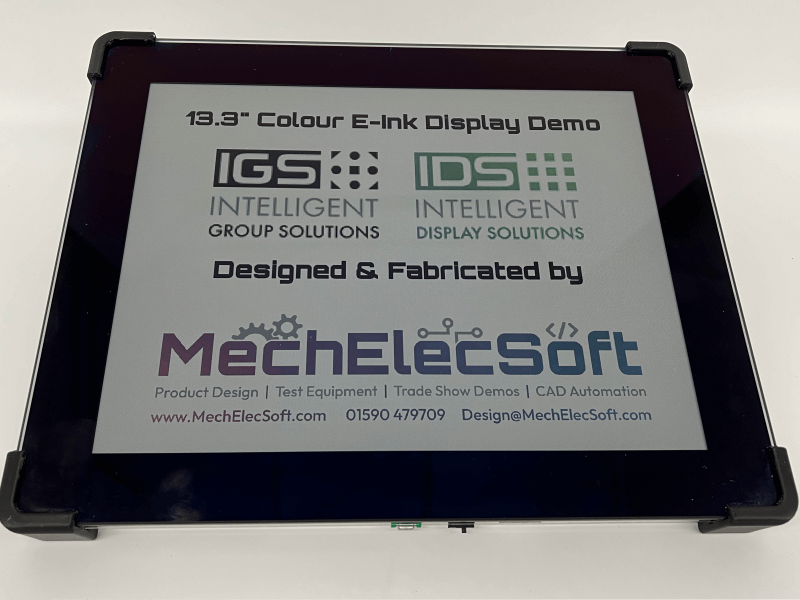

13.2 Inch Colour Ink Demo for Intelligent Group Solutions.

IGS wanted a nice looking and practical demo for sales guys. E-Ink included a backlight and driver board. Neatly arranged all the required PCBs into the acrylic casing with 3D printed corner pieces to hold in place. Can be attached to PC via USB.

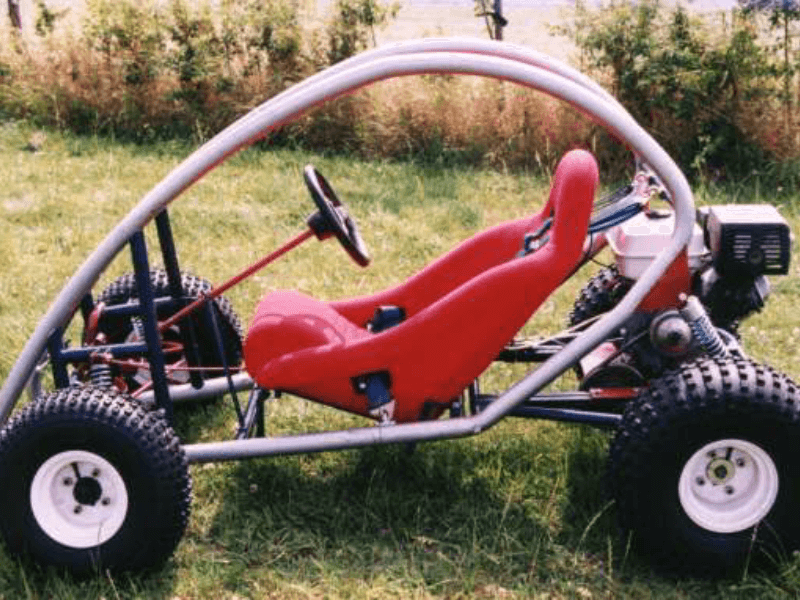

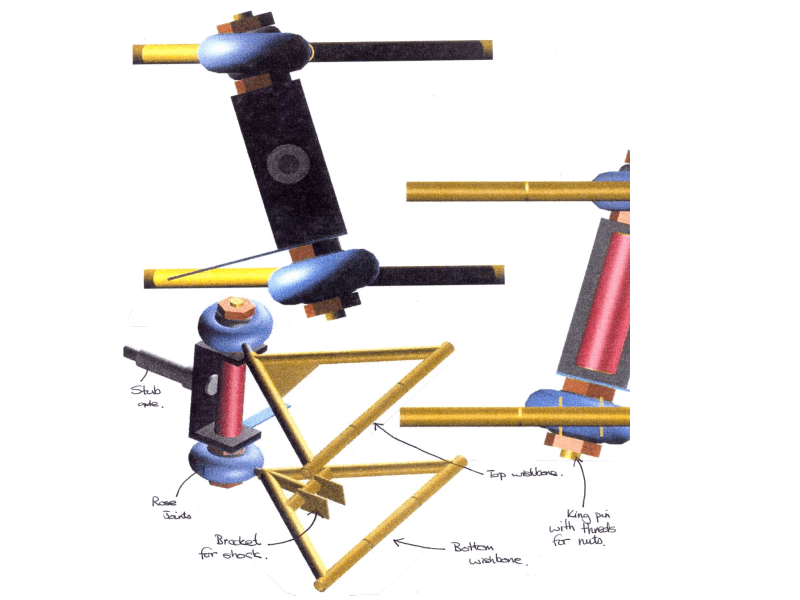

All Terrain Buggy

Nigel's GCSE School project from back in 1997! 8HP Honda engine, full suspension, hydraulic disc brake, torque converter. Clocked at 32mph!

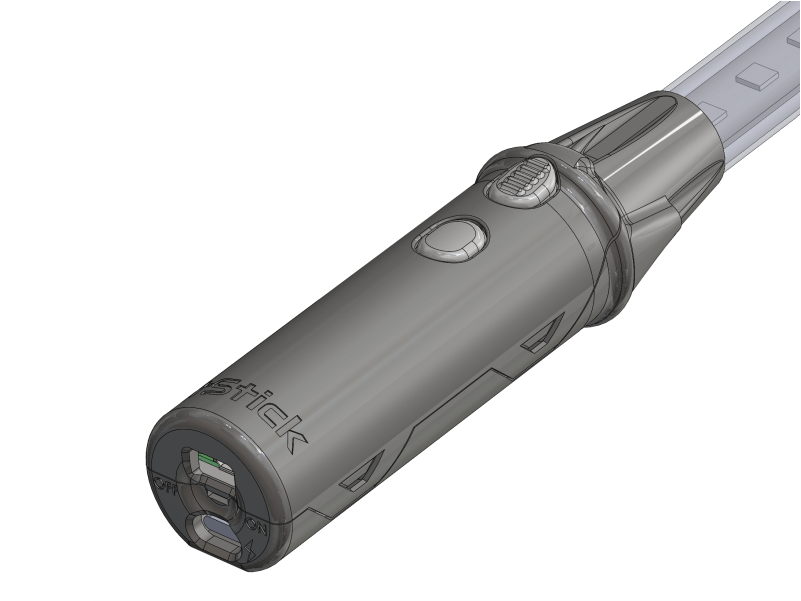

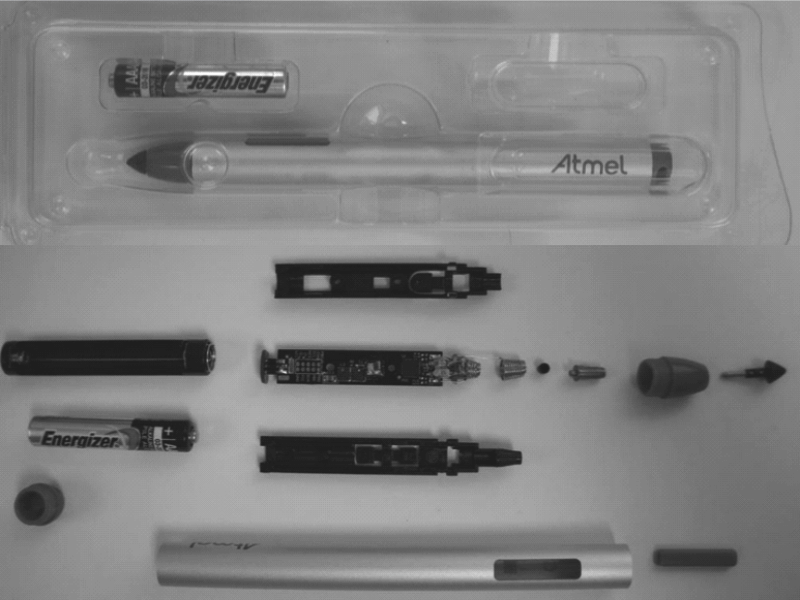

Atmel mXTS200 Active Stylus EVK

Nigel was the lead mechanical engineer for the development of Atmels MaxStylus active stylus. Worked with partner manufacturers based in Taiwan & China to produce and put into production the Atmel active stylus and customer designs. Involved from initial concept generation to mass production, customer support and consultation. Included Asia visits for design phases, trial builds, production runs, testing and support. This particular Atmel development stylus features a replaceable AAAA battery.